🔥 Designing Sprinkler Systems for Palletized and Shelf Storage: Key NFPA 13 Guidelines (and How to Simplify Them)

Designing fire protection systems for warehouses and storage areas isn’t just about meeting code—it’s about understanding the details that drive safety and compliance. One of the most technically dense areas in NFPA 13 is Chapter 14, which covers protection requirements for:

-

Palletized storage

-

Solid-piled storage

-

Bin boxes

-

Shelf and back-to-back shelf storage

This chapter applies to Class I through Class IV commodities, and depending on your storage height and packaging type, the protection design can become complex very quickly.

In this article, we’ll break down the essential guidelines, and introduce a tool that helps simplify the entire process.

📦 Understanding the Storage Types and Key Variables

NFPA 13 recognizes several factors that affect sprinkler system design for these storage methods. Among the most important are:

-

Commodity Type: Whether the materials are Class I–IV, and whether they are encapsulated (wrapped on all sides in plastic) or non-encapsulated.

-

Storage Height: Most design criteria shift significantly when storage exceeds 12 ft (3.7 m) or 15 ft (4.6 m).

-

Configuration: Are goods stored on open shelves, stacked pallets, or in racks? Are there walkways or barriers?

These distinctions determine the required sprinkler density, design area, and system type.

💧 Choosing the Right Sprinkler Approach

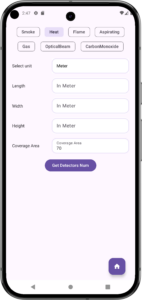

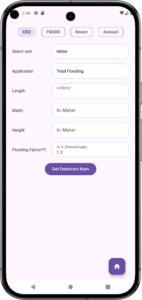

There are three primary sprinkler types that NFPA 13 allows, depending on the scenario:

1. CMDA – Control Mode Density/Area

Used in most standard storage situations. Design involves selecting appropriate density and area combinations from charts and curves based on commodity and height.

2. CMSA – Control Mode Specific Application

Used for higher-challenge commodities or where higher flow is required with specific sprinkler types. Often requires maintaining specific operating pressures and number of sprinklers in the design area.

3. ESFR – Early Suppression Fast Response

Designed to suppress fires early in high-challenge storage configurations. Requires higher pressures and specific layout criteria—often 12 sprinklers (4 per branch line over 3 lines).

📊 Key Design Parameters to Consider

Depending on your setup, NFPA 13 will require you to determine:

-

Required sprinkler discharge density (gpm/ft² or mm/min)

-

Design area (often in ft² or m²)

-

Minimum operating pressure

-

Pump capacity and water supply duration

-

Tank volume (for areas without adequate municipal supply)

Each of these values must be selected based on commodity class, height, and system type, referencing tables and design curves found throughout the standard.

Here’s where many designers spend significant time flipping through the code, validating assumptions, and checking their math…

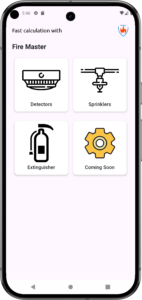

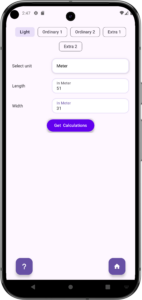

⚙️ How FireMaster Simplifies the Process

To streamline this effort, we built FireMaster—a mobile tool engineered for fire protection engineers and professionals.

With FireMaster, you can:

-

Select the storage type, commodity class, and height

-

Instantly get the correct design density, area, and sprinkler requirements

-

Access NFPA-compliant logic without needing to reference multiple chapters

-

Use built-in “Tech Bits” for fast lookups of common configurations

-

Export results and calculations in clean, shareable formats

Whether you’re in the design phase, doing code review, or checking field installations, FireMaster helps keep your decisions fast, accurate, and NFPA-aligned.

🚀 Ready to Try It?

If you work in fire protection design and want to save hours of manual lookup time, give FireMaster a try.

It’s designed to turn the dense NFPA requirements into a fast, field-ready workflow.

📱 Available now on Google Play.

https://play.google.com/store/apps/details?id=com.alienshome.firemaster

Also see

FireMaster: Your Ultimate Guide to Fire Protection System Calculations 🔥🚒